CUSTOMER: Mediterranean Shipping Company

CHALLENGE: Manage volumes of data, process and validate it in real time, and make it available.

OUTCOME: After a short (six-month) implementation, InterSystems data platform empowers MSC to provide its customers with precise information about their shipments.

As the largest container shipping company in the world, Mediterranean Shipping Company (MSC) has a fleet that annually transports more than 12 million containers loaded and cleared in some 270 ports.

Handling transport and its associated process chain is complex. It is affected by uncontrollable situations such as bad weather and strikes. And it is accompanied by immense volumes of data and information: certificates of origin, documents of title to goods, way bills, bills of lading, commercial and customs invoices, and packing lists, to name but a few.

The central IT system in Geneva has to electronically process and validate more than 300,000 transactions each day. MSC has set a goal of processing the enormous volume of information in real-time, so that customers can see the current status of their freight using the web-based Tracking and Tracing tool.

In the transportation sector, the containers and papers dictate the route and planning because, given the long supply chain, outside influences such as a strike, a storm, missing papers, or an error by the tracking companies, can result in repeated changes.

For this reason, a clear workflow has to be provided that can track and record the current course of the process, and when unplanned changes occur, automatically authorize consistent and logical steps. “Ship transport is just a small part of the entire transport and supply chain. But it is extremely critical. Many customers who trust us with their freight depend on precise and current delivery information for the planning of their company activities,” says Rumen Lilov, eBusiness Development Manager at MSC. “This is why it is important to us that they receive the time status for their delivery. And specifically, from when it is accepted at the port until it is delivered at its destination.”

Existing Technologies Could Not Meet the Requirements

The relational database in use at MSC could not achieve the set goals. It was unable to manage the volumes of data, process and validate it in real time, and make it available without delay to the MSC agency network worldwide and customers via Tracking and Tracing. When searching for a possible solution, MSC came upon InterSystems data platform technology and subjected the technology to strict due diligence.

Developed and Implemented Cost-Effectively in Six Months

“InterSystems data platform, with its embedded, highly scalable, reliable, and SQL-compatible database, contains all the integration and reporting functions that we need, including EDI Engine. And thanks to its flexibility and versatile modeling capabilities, it also provided for fast development. After only six months we achieved our goal,” explains Rumen Lilov. “This unique technology is the best-kept secret in the IT industry.” MSC is now able to process the data in real time, make it available through a clear workflow, and provide its customers around the globe with precise information about their freight and integrate that information in its EDI Engine. The shipment can be tracked in real-time via the internet. Thanks to the email and RSS alerts integrated into the Tracking and Tracing system, MSC customers can remain actively informed about every movement of their containers.

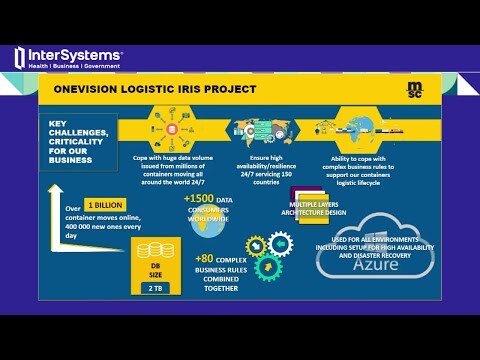

Mediterranean Shipping Company Digital Transformation Journey

Successfully Integrated in Peripheral Systems

The solution is fully integrated into the company IT and peripheral systems. And thanks to data processing in real-time, errors by the MSC agencies at various locations that are transmitted via EDI are detected quickly, localized, and corrected by appropriate measures. Errors may include, for example, illogical actions, date or time periods, incorrectly recorded destination ports or warehouses, and procedures entered twice. These errors are transmitted automatically to MSC agencies, who can react immediately on-site and correct the error. As soon as the data is validated and processed centrally, it is forwarded directly to the MSC backbone. The agencies access the data using the Microsoft SQL Server Framework and can work in various applications in a timely manner. “With the selected solution, we can bring together the best of different providers,” says Rumen Lilov. “And the support from InterSystems was excellent. We had just a few issues where we needed support. And with each request, the contact person quickly comprehended the task and presented target-oriented solutions.”

Dashboards Provide “Just-In-Time” Analytics at the Point of Action

MSC uses InterSystems embedded business intelligence technology to provide its agencies around the world with dashboards showing the up-to-the-minute status of all its stock. Local offices no longer have to request ad hoc reports from the Geneva office. They can meet country-specific requirements using their own reports and templates.