InterSystems IRIS and the Smart Factory Starter Pack for Manufacturing

Manufacturing organizations today are rapidly transforming their existing factories into “smart factories.” In a smart factory, data from Operational Technologies (OT) systems and real-time signals from the shop floor are combined with enterprise IT and analytics applications to enable manufacturers to improve quality and efficiency, respond faster to events, and predict and avoid problems before they occur, among many other benefits.

The smart factory market accounted for $153 billion in market value in 2019 and is expected to reach $245 billion by 20241 and 70% of manufacturers surveyed are already implementing smart factory initiatives.2

New technologies are making it easier than ever for manufacturers to transition their existing factories that use legacy machines, controllers, and software, without requiring a rip-and-replace, allowing them to seamlessly leverage their existing investments in machinery and technology.

InterSystems IRIS and the Smart Factory Starter Pack are helping manufacturers “fast track” their smart factory initiatives. Their powerful capabilities provide a number of important benefits, including:

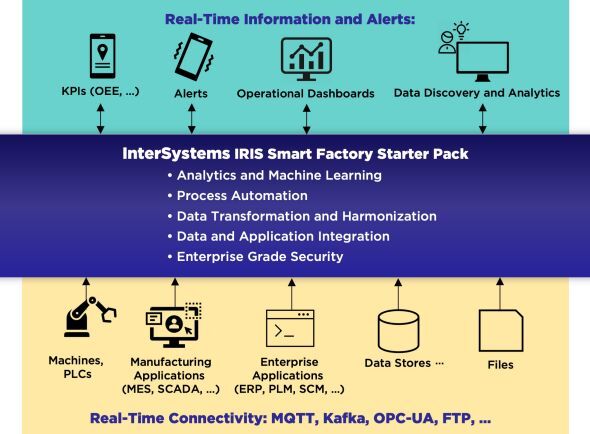

Connectivity: InterSystems IRIS and the Smart Factory Starter Pack provide real-time, high throughput connectivity to machines (via the OPC-UA standard machine to machine communication protocol for industrial automation), manufacturing software (e.g. MES systems), ERP systems, data warehouses, business intelligence and analytics software, and more.

Transparency: IT and OT data is integrated, transformed and harmonized into a consistent and unified format to provide a comprehensive real-time operational cockpit spanning all relevant systems and data. Critical performance data, as well as calculated Key Performance Indicators (including Overall Equipment Effectiveness) are presented in real time to the relevant personnel through dashboards, alerts, and other mechanisms.

Predictive Intelligence: Artificial intelligence (AI) and machine learning (ML) algorithms that leverage integrated and harmonized data from across the organization are used to enable predictive maintenance, to predict manufacturing quality, and to identify problems in advance so that they can be prevented from occurring.

Real Time Operational Intelligence: AI and ML algorithms (as well as business rules and other analytics functions) can be embedded into real-time processes, so that intelligent programmatic actions can be triggered automatically in response to real-time signals from the shop floor.

Agility: Business users and analysts can visually navigate through the data and optimize processes using a low code graphical interface, within the boundaries that can be set by the organization.

For more information, please visit

InterSystems.com/Manufacturing

To download the Starter Pack, visit

OpenExchange.InterSystems.com

1 Source: https://www.statista.com/statistics/872289/worldwide-smart-factory-market-size/ 2 Source: Capgemini Research Institute, Smart Factory Survey, April-May 2019, N=1348 manufacturers.